PRODUCT FINDER

Which products are best for you?

P610 Programmable Core Cutter

Appleton P610 Core Cutter – Large Core Capacity in a Programmable Core Cutter

The P610 Programmable Core Cutter can process parent cores from 3” to 24” ID (with appropriate tooling) with wall thicknesses to 1” and up to 30 feet in length. The P610 has the flexibility to cut parent cores of varying lengths due to its ability to sense the end of the core and start the next cutting cycle and is easily adjusted for different core ID’s by simply changing the chuck and cutting pad.

Specs

Parent Core Length Range

Core Diameter Range

Wall Thickness

Auto Indexing Knife

Cut Length Range

Cut Length Tolerance

Utilities

Options/Upgrades

Options

Units of Measure

Cutting Pad and Chuck Jaw Set

Length

RS232 Serial Interface

Additional Cut Set Storage

Special Paint

Electrical Components

Updates

Automated Core Handling

Short Core Tray or Full Length Core Tray

Core Printer

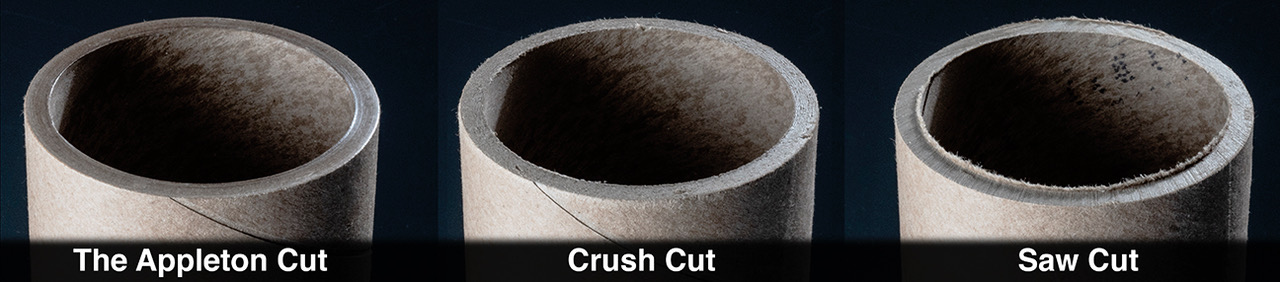

The Appleton Cut

Appleton Manufacturing is the only core cutter manufacturer utilizing the specific combination of a fixed knife to slit the core and internally-driven core rotation while supporting the inner ply with a carbide pad, which is used to pinch the inner ply of the core between the cutting edge of the knife, allowing for a consistently accurate and clean cut all the way through the core. This technology allows for every core cut on an Appleton to have a crisp, clean and virtually dust-free polished cut. It’s what we at Appleton call “The Magic of the Appleton Cut”.

Appleton Manufacturing’s Core Cutters offer several benefits to slitting a core as opposed to saw or crush cutting them:

Appleton’s cutting technology is available on all Appleton Core Cutters from our basic Semi-Automatic S210, through our Automatic A301 and A400s, as well as the Programmable P510 and P520 and up to our fully automated P610 and Multiple Diameter High Speed (MDHS) cutters.

Lower Quality Core Cutting Types

Which products are best for you?

Back to Top