PRODUCT FINDER

Which products are best for you?

P5 Programmable Core Cutters

P5 Core Cutters also come with an outstanding promise of support. If you should need technical assistance, service or replacement parts, Appleton will be there for you. Appleton still provides parts and service for core cutters built over 60 years ago – you can be assured our tradition of superior support will bring long-term value to your Appleton core cutter investment.

P520

Appleton P520 Core Cutter – Increased Speed & Advanced Programmable Core Cutting

The P520 features automated core feeding, advanced programmable control for enhancing cut-to-length performance and a PLC control with touchscreen display for exceptional flexibility. The PLC integrates easily with optional automated parent and cut core handling systems for enhanced automation and labor reductions. In addition, the P520 offers improved speed and accuracy over previous P5 Series Core Cutters.

P520 includes the following enhancements over prior P5 series cutters:

Parent Core Length Range

Core Diameter Range

Wall Thickness

Cut Length Range

Controls

Cut Length Tolerance

Utilities

P510

Appleton P510 Core Cutter – Advanced Programmable Core Cutting

The P510 features automated core feeding, advanced programmable control for enhancing cut-to-length performance and a PLC control with touchscreen display for exceptional flexibility. The PLC integrates easily with optional automated parent and cut core handling systems for enhanced automation and labor reductions.

Parent Core Length Range

Core Diameter Range

Wall Thickness

Cut Length Range

Controls

Cut Length Tolerance

Utilities

Options

Short Core Tray or Full Length Core Tray

Stroke Limit

RS232 Serial Interface

Knives

Control Key Lock-Out

Additional Cut Set Storage

Electrical Components

Upgrades

Patented IDC (Instant Diameter Change) Mandrel System

Auto Indexing Knife

Automated Core Handling

Core Printer

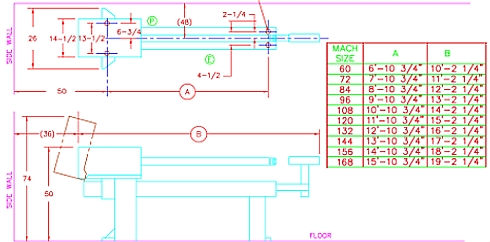

Layout

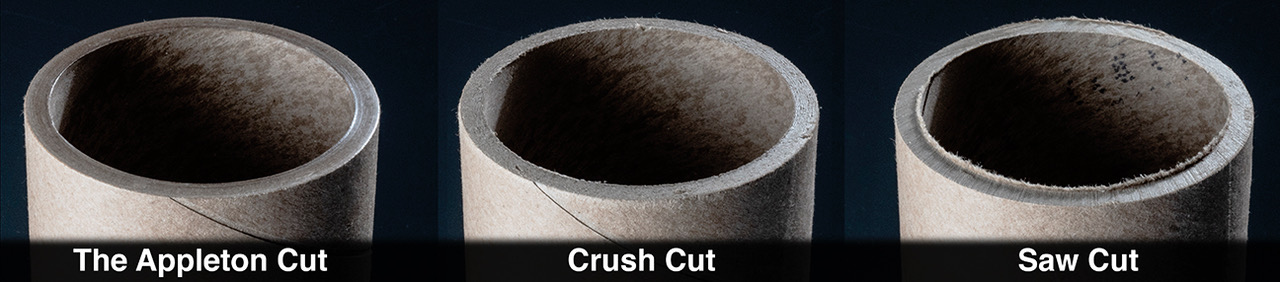

The Appleton Cut

Appleton Manufacturing is the only core cutter manufacturer utilizing the specific combination of a fixed knife to slit the core and internally-driven core rotation while supporting the inner ply with a carbide pad, which is used to pinch the inner ply of the core between the cutting edge of the knife, allowing for a consistently accurate and clean cut all the way through the core. This technology allows for every core cut on an Appleton to have a crisp, clean and virtually dust-free polished cut. It’s what we at Appleton call “The Magic of the Appleton Cut”.

Appleton Manufacturing’s Core Cutters offer several benefits to slitting a core as opposed to saw or crush cutting them:

Appleton’s cutting technology is available on all Appleton Core Cutters from our basic Semi-Automatic S210, through our Automatic A301 and A400s, as well as the Programmable P510 and P520 and up to our fully automated P610 and Multiple Diameter High Speed (MDHS) cutters.

Lower Quality Core Cutting Types

Which products are best for you?

Back to Top