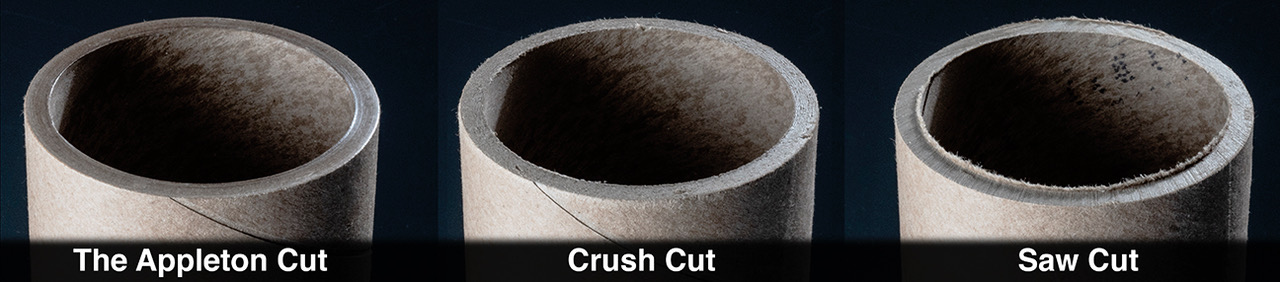

Appleton Manufacturing is the only core cutter manufacturer utilizing the specific combination of a fixed knife to slit the core and internally-driven core rotation while supporting the inner ply with a carbide pad, which is used to pinch the inner ply of the core between the cutting edge of the knife, allowing for a consistently accurate and clean cut all the way through the core. This technology allows for every core cut on an Appleton to have a crisp, clean and virtually dust-free polished cut. It’s what we at Appleton call “The Magic of the Appleton Cut”.

Appleton Manufacturing’s Core Cutters offer several benefits to slitting a core as opposed to saw or crush cutting them:

Appleton’s cutting technology is available on all Appleton Core Cutters from our basic Semi-Automatic S210, through our Automatic A301 and A400s, as well as the Programmable P510 and P520 and up to our fully automated P610 and Multiple Diameter High Speed (MDHS) cutters.

Lower Quality Core Cutting Types

Saw Cutting

The saw cutting of cores is achieved via 1/8” thick blade that removes an 1/8” of core material. This results in the costly loss of core material (1” of material lost for every 8 cuts), and the material being removed is turned into airborne dust which is a breathing hazard, a local contaminant and can cause issues with downstream operations. This creates a situation that must be mediated by using noisy vacuum systems which must be cleaned and maintained at regular intervals. It is especially a problem in those industries where it is necessary to be clean and debris-free, such as the food packaging and healthcare-related industries. While accuracy tends not to be an issue for saw cut cores, the quality of the cut itself generally has inner ply tearing, outer ply tabbing and consistently rough core-edge scarring.

Crush Cutting

Crush-type cutters use a rotating blade when cutting cores. As the rotating blade makes its way through the core material the vibration and movement in the cutting system decreases accuracy in core lengths and creates a jagged edge on the core. At the end of the cut, the rotating blade comes to rest against a soft anvil. This quickly creates a ridge in the anvil and allows the inner ply of the core to be crushed inward, creating an imperfection that causes core problems in downstream operations. Another liability of the crush cut method, is that the rotating saw introduces a large amount of dust into the air and the surrounding environment This creates breathing hazards and maintenance problems that must be mediated by using noisy vacuum systems which must be cleaned and maintained at regular intervals.