PRODUCT FINDER

Which products are best for you?

A301 Automatic Core Cutter

Appleton A301 Core Cutter – Entry Level Automated Core Cutting

The A301 is the ideal model for any company’s entry into automated core cutting. This rugged, yet affordable, fixed-knife core cutter automatically advances and cuts the core to precise, pre-set lengths while requiring minimal operator attendance. It’s the perfect tool for producing quality, low-to-high-volume, batch-cut cores in-house quickly and cost-efficiently.

Specs

Parent Core Length Range

Core Diameter Range

Wall Thickness

Cut Length Range

Maximum Length

Cut Length Tolerance

Utilities

Options/Upgrades

Options

Stroke Limit

Extended Target

Large Core Diameter

Additional Support Rollers

Knives

Electrical System Controls

Upgrades

Digital Readout

Auto Indexing Knife

Patented IDC (Instant Diameter Change) Mandrel System

Automated Core Handling

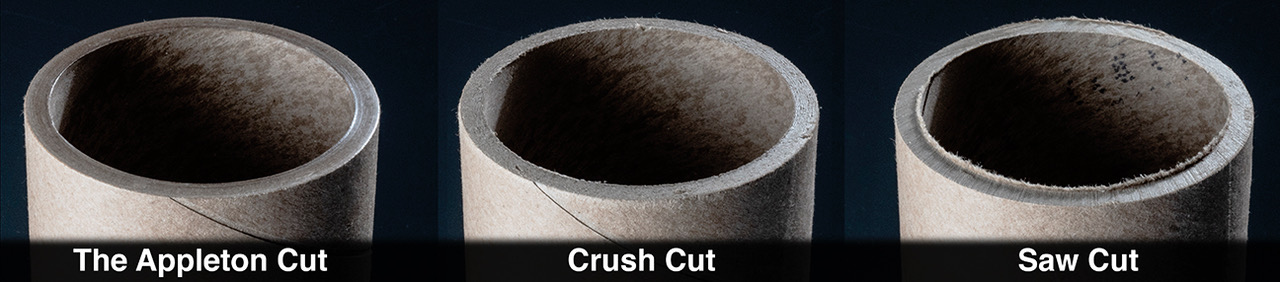

The Appleton Cut

Appleton Manufacturing is the only core cutter manufacturer utilizing the specific combination of a fixed knife to slit the core and internally-driven core rotation while supporting the inner ply with a carbide pad, which is used to pinch the inner ply of the core between the cutting edge of the knife, allowing for a consistently accurate and clean cut all the way through the core. This technology allows for every core cut on an Appleton to have a crisp, clean and virtually dust-free polished cut. It’s what we at Appleton call “The Magic of the Appleton Cut”.

Appleton Manufacturing’s Core Cutters offer several benefits to slitting a core as opposed to saw or crush cutting them:

Appleton’s cutting technology is available on all Appleton Core Cutters from our basic Semi-Automatic S210, through our Automatic A301 and A400s, as well as the Programmable P510 and P520 and up to our fully automated P610 and Multiple Diameter High Speed (MDHS) cutters.

Lower Quality Core Cutting Types

Which products are best for you?

Back to Top